Welcome to Micon Mould

Welcome to Micon Mould

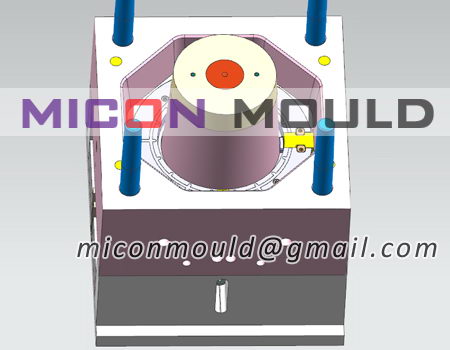

Bucket mould is one of our most important plastic injection mould, our bucket mould includes thin wall bucket mould, food bucket mould, pail mould, cylinder bucket mould, square shape bucket mold,cuboid bucket mould, industrial use bucket and pail mould, industrial paint bucket mould, oil bucket mould, packing bucket mould, dustbin bucket mould, cement pail mould, plastic barrel mould and other bucket moulds.

Firstly, Mould Design and Structure

A high-quality mold structure is a premise for a qualified mold before manufacturing.We attach great importance to analyze mold structure, including demolding draft angle, the epitome of product surface, gating system design, exhaust design, cooling system design etc.The main problems that may easily occur will through trial and error during the mould structure design.

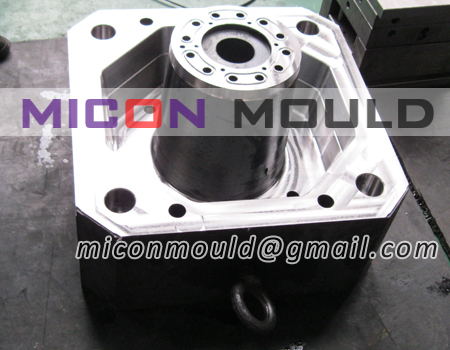

2. Second, the Mould Steel

In order to improve the mold life and product quality, we increase the mold steel hardness through heat treatment. The steels we commonly use are H13(48-52HRC), 2316(45-50HRC) etc.to prevent mould eccentric, we use whole piece of steel to make the bucket. The cooling system is very important. We adopt single loop cooling way and setup even distribution water channels as much as possible. To enhance the cooling effect, BeCu can be inserted on the core and cavity, see pictures as below:

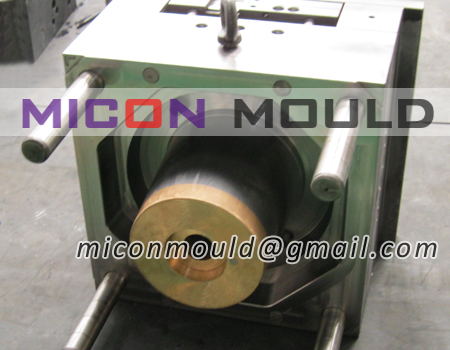

Our bucket moulds use air assistance,stripper plate and centre ejector for demolding (release in two steps).In order to increase cooling performance, there also have water channels in the centre.

All small sliders will be nitrided to increase the hardenss.

It is important to keep maintenance for the moulds. We should check and make sure the the water channels and air circuit unlocked. Add lubricant oil for the siliders, regularly clean the stripper plate and centre ejector.

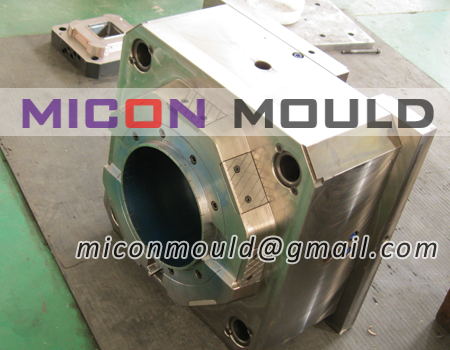

3. Third, the Mould Cooling system

Cooling system design is a relatively cumbersome work, namely to consider the uniformity of the cooling and the cooling effect, also the impact brings to the overall mold structure, determining the exact location and size of the cooling system; and cooling for key positions such as moving plate or the inserts, side sliders as well as side cores; standard cooling element design and the selection of the cooling standard components. Micon mould analyzes all series of factors when begin to start the mold design. The mold has recycled water to flow in every part of it which reduces the cooling time, improves the production efficiency and greatly reduces products costs.

To enhance the cooling effect, BeCu can be inserted on the core and cavity, see pictures as below:

4. Choose suitable tonnage injection machine for the mould. Take records for the injection pressure, speed and temperature etc when injection molding.

5. According to the customer's agreement on weight, plastic materials and demoulding, send qualified samples to customers as well as mould test videos.

6. It is important to keep maintenance for the bucket moulds. We should check and make sure the the water channels and air circuit unlocked. Add lubricant oil for the siliders, regularly clean the stripper plate and centre ejector.